Where to use the high voltage patch lamp beads

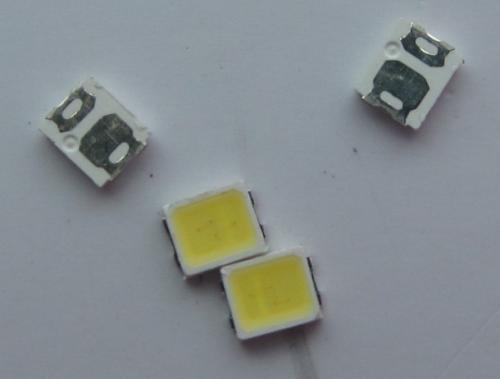

The packaging process of SMD LED is to equip fluorescent powder and epoxy resin, Make a mold, and then make the epoxy resin with fluorescent powder into a rubber cake, and stick the rubber cake on the chip, fill the epoxy resin around, and then make the SMD encapsulated led, so directly stick the thermal conductive adhesive on the surface of the heat sink, and then make the heat dissipation improved greatly, so that the reliability is greatly improved, and the light decay is also reduced. What are the characteristics of the chip mounted LED lamp beads?

1. It can be arbitrarily zigzagged and fixed on the concave convex surface. Compared with other LED chip packaging, when it adheres to the same junction temperature, it reduces the requirements for heat dissipation components. When the same heat dissipation components are used, it reduces the break temperature and prolongs the life of LED packaging.

2. The thermal resistance of the chip LED lamp bead has a decisive influence on the life of the LED chip, especially for the LED chip driven by large current, the cost and heat dissipation performance of the LED packaging product depends on the structure of the packaging bracket.

3. Compact volume, rich color, high brightness, adjustable luminous angle, equipment and length can be customized according to requirements.

4. Energy saving and environmental protection: constant current drive, ultra-low power consumption, electro-optical power close to 100%, no UV, infrared radiation, no heat.

-

04-28

How to reflow Guangdong LED chip lamp bead

Now plug-in lamp beads and chip lamp beads are required to be reflow welded, so the lamp beads can basically be under 240 ℃.If the LED lamp bead is reflow welded, the reflow temperature must be set, o

-

04-28

How to deal with the leakage of high voltage chip lamp beads

1. The primer is too thick, which leads to leakage.2. For example, when the lamp bead is welded, the improper operation of the wire welding machine causes the excessive pressure when the magnetic nozz

-

04-28

How to use the high voltage chip lamp beads

The application of LED chip lamp beads is more and more widespread. Its development trend is involved in all major professions. In the process of high-quality development, no one can ensure that there

-

04-28

Where to use the high voltage patch lamp beads

The packaging process of SMD LED is to equip fluorescent powder and epoxy resin, Make a mold, and then make the epoxy resin with fluorescent powder into a rubber cake, and stick the rubber cake on the

简体中文

简体中文 English

English